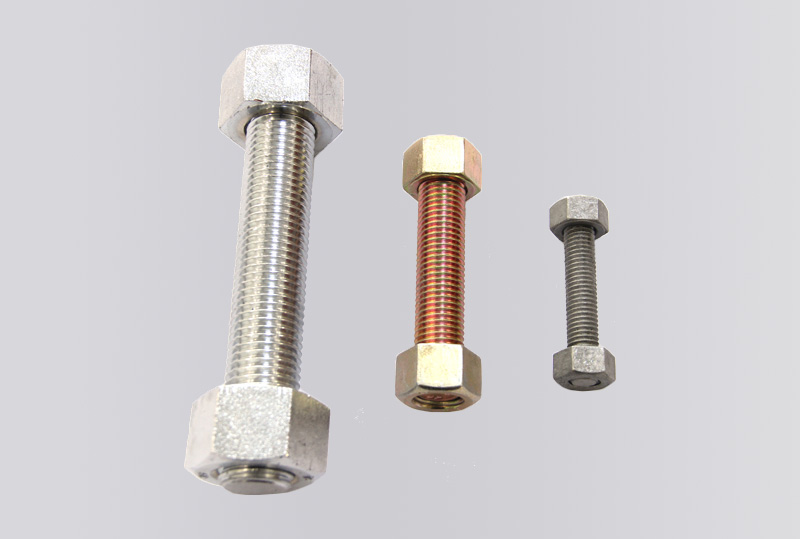

Friends who have been in the metal manufacturing industry must have some knowledge about pickling. Pickling is to remove the oxide film on the metal material and at the same time remove oxide film, a layer of phosphate should be formed on the surface of the metal. The film, don't underestimate this layer of film, it will play a certain role in the subsequent spraying or molding process. It has to be said that such pickling is like putting a new piece of clothing on the metal surface, and it is a new piece of clothing that must be worn. From this point of view, pickling is also a necessary step for us, and it must be done in place without being careless. Let's take a look at the process of making pickling with Hex Nut .

The first is to master the concentration and temperature in the pool. Under this premise, pour the disk into the pool that we have prepared. The first step is to remove the oxide film on the metal surface.

The second step is to change the pool. The step here is called clear water. The main function is to remove the corrosive substances on the surface.

The third step, oxalic acid, is to increase the activity of the metal and lay the foundation for the next ethical coating.

In the final step, the phosphate is in contact with the surface of the metal material to form a coating. Next, use clean water to remove the residue. Such steps may seem simple, but we have to have a good grasp of the time during operation. This kind of mastery requires the operator to have a good grasp of the time. Otherwise, pickling is a transition and has no practical significance. The steps are just not possible to implement. It can be said that pickling is a transitional period for Hex Nut production. Such a step must be well realized in order to do our following process well and meet certain quality requirements.