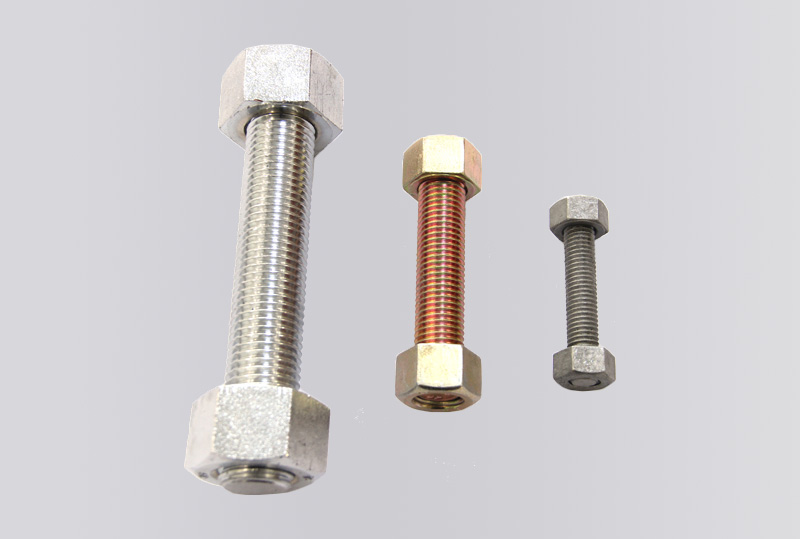

Due to the design and use of stud bolts, the choice of bolt material is more inclined to steel bolts, and there are special requirements for material processing performance in the thread production process. When making bolts, you should carefully consider the weight, price, purchase, etc., and insert the screws in the mechanical properties of the screws (especially the strength of the material), and require the conditions of the screws and the corrosion resistance of the material. As a special requirement of the working temperature for the heat resistance of materials, steel has the advantages of beautiful appearance, clean, environmental protection, low cost, good safety performance, and good impact resistance.

Stud Bolt Supplier introduced that in the production process of stud bolts, considering that stud bolts are mainly used for situations that require frequent removal of connections, this type of bolt is also required for the installation, use, and processing of much mechanical equipment. Therefore, its bearing capacity is high, but it will be corroded in long-term use. Therefore, the stud bolts should be properly maintained during use to strengthen the maintenance and use of the bolts. Choose a suitable storage place and warehouse, maintain ventilation, pay attention to changes in the weather, and avoid the rain. Or impurity erosion.