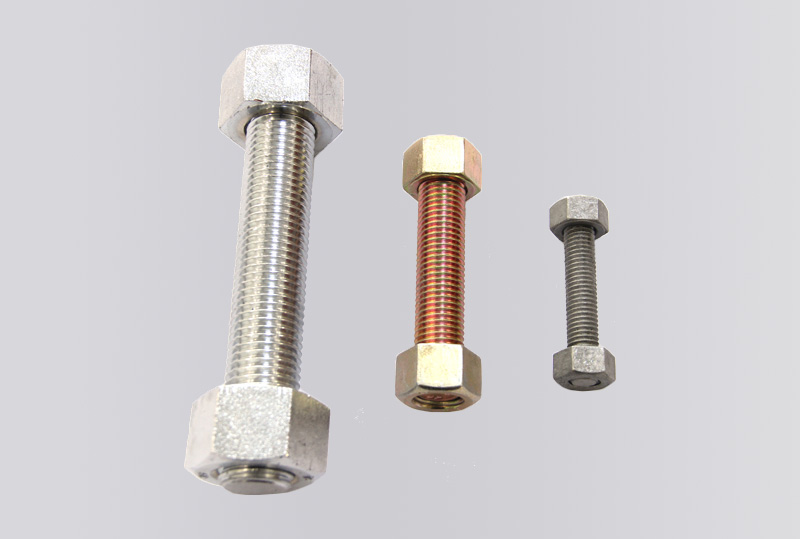

Fixing tips for 2H Heavy Hex Nut :

1. Add a washer

As a part to prevent bolts and nuts from locking, flat washers are basically used in places where fasteners are used. Flat washers mainly play the role of increasing the contact area and tightening between products. The contact area can reduce the damage caused by the friction between the parts, and can also reduce the pressure between the nut and the equipment, thus playing a protective role. The spring washer has a good anti-loose effect and anti-vibration effect. Generally, the thread direction is right-handed, while the helical direction of the spring washer is left-handed. After the nut is tightened, the elastic reaction force generated by the flattening of the washer makes the screwed threads tightly compressed. In the case of relatively large dynamic loads and vibration loads, we can use a combination of flat washers and spring washers. In addition to spring washers and flat washers, there are various styles of washers that can be used as needed. Adding a washer can increase friction and cushioning, protect the surface of the connected piece from being scratched by the nut, and disperse the pressure of the nut on the connected piece.

2. Self-locking nut

Self-locking nuts are generally self-locking by friction, mainly to prevent loosening and vibration. The types of self-locking nuts classified by function include those with nylon rings, those with neck closures, and those with metal anti-loosening devices. They are all effective torque locknuts. The principle is to press the embossed teeth into the preset holes of the sheet metal. Generally, the diameter of the square preset holes is slightly smaller than that of the pressure riveting nut. The nut is connected to the locking mechanism. When the nut is tightened, the locking mechanism locks the ruler body, and the ruler frame cannot move freely to achieve the purpose of locking; when the nut is loosened, the locking mechanism disengages the ruler body, and the ruler frame edge The ruler moves. Common self-locking nuts include high-strength self-locking nuts, nylon self-locking nuts, swimming self-locking nuts, and spring clip self-locking nuts.

3. Double nut to prevent loosening

A left-handed nut and a right-handed nut are used to tighten and prevent loosening. After the two nuts are tightened, the axial force generated between the nuts increases the friction between the nut teeth and the bolt teeth, thereby preventing the nut from automatically loosening.

4. Screw and nut drilling and pinning

The main purpose of pinning is to prevent rotation. After the nut is tightened, insert the pin into the nut slot and the bolt tail hole to prevent the relative rotation of the nut and the bolt. Most of the work of general machinery is repetitive, and some are accompanied by strong vibration and impact. After a long time, the threads that are originally tightly meshed together will produce tiny gaps or even deformation. In machinery, pins are mainly used for assembly positioning, and can also be used as overload shear connections for connection, anti-loosening, and safety devices. The types of pins include cylindrical pins, tapered pins, hole pins, cotter pins, and safety pins.

5. Series steel wire anti-loosening

The anti-loosening of the series steel wire is to insert the steel wire into the hole of the head of the bolt and connect the bolts in series to play the role of mutual restraint. This anti-loosening method is very reliable and economical and can prevent loosening caused by high-frequency vibration, especially for engines, turbojets, etc. that operate in high-temperature environments. It is often used in aircraft and rockets. The disadvantage is installation and disassembly. Very time-consuming.