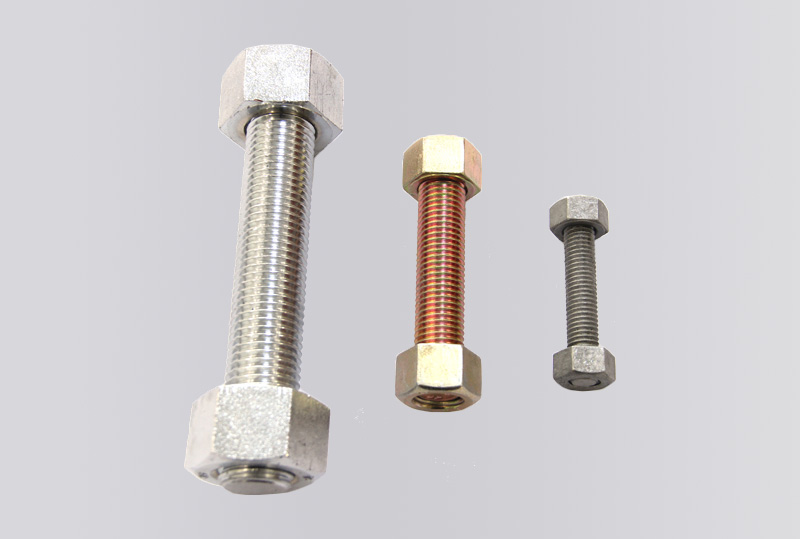

2H Heavy Hex Nuts Suppliers introduces the nut-forming process:

1. Cutting: The scissors mold and scissors cooperate to cut the wire into the required blank.

2. First punching: the front punching die, stroke die, and rear punching rod cooperate to shape the unevenly deformed blank, and the rear punching rod pushes the billet out.

3. Second punch: the flip clamp clamps the billet from the first punch to the second punch, further shapes the billet, and strengthens the flattening and filling effect of the first punch, and then the billet is pushed out by the rear punch.

4. Three-punch: Turn over the clamp to clamp the blank from the second punch to the third punch. The front punch die, stroke die, and rear punch rod cooperate to squeeze the billet again so that the lower punch can be completely formed, and then the rear punch rod will press the billet. The billet is rolled out.

5. Four-punch: Turn the clamp to clamp the blank from three-punch to four-punch. The front punch dies, stroke dies, and rear punch rod cooperates to completely form the nut and adjust the thickness of the nut by controlling the thickness of iron filings. The back punch pushes the billet out.

6. Five-punch: Turn over the clip to clamp the blank from four-punch to five-punch. With the cooperation of the front punch and the stripping plate, the fully formed blank is punched, and the punched iron filings enter the lower core of the punching die, and Finally, the forming of the nut is completed. The head marks of the nut are also formed during this process.