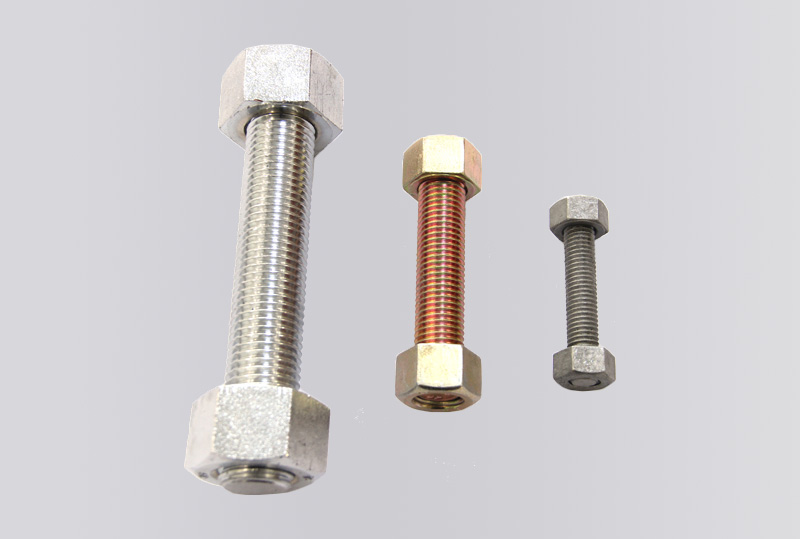

2H Heavy Hex Nuts Manufacturers introduces the production process of cap nuts:

1. The one-piece whole can be formed by cold piers, and the products with large specifications and low output can be red punched and then cut.

2. Combination type, the nut body, and the cap are separated structures, and the two are connected by different connection methods. When the split structure is adopted, the existing standard nut can be used for the nut body, and the cap of the cold pier only needs to be connected to the nut during processing. This structure reduces the difficulty of manufacturing. There are many process methods for combined connection, and there are also many patented products.

(1) The nut body and the cap can be connected by riveting deformation, the sealing performance is poor, there is a certain gap, and the joint is prone to leakage.

(2) Welding is the most commonly used joint connection between the nut body and the cap, among which butt welding (ie butt welding) is a type of resistance welding. It is to heat the connection end of the nut and the cap to a plastic or molten state through an electric current to form a permanent connection under the action of axial pressure.